Control arms are used for better handling of a vehicle. They are considered to bethe suspension components that link the wheels to the vehicle. This essay will focus on the importance of control arms, their types and how they enhance the performance characteristics and safety of vehicles. It is also up raised that even though the role of control arm appearances so simple but assisting the owners of the vehicles in the understanding of control arm functions may help them in decision making for the control arm upgrades or maintenance.

Most people refer to control arms as A-arms, and they are quite like the wheels to travel up and down but remain in scope of the body of the vehicle. This is important because it helps to achieve better contact between the tires and the surface of the road, thus enhancing a vehicle’s handling, ride comfort and promoting the uniform wear of tires. In the absence of adequate performance of control arms for instance a classic A arm, handling of the vehicle may be poor with the loss of driving experience as a result.

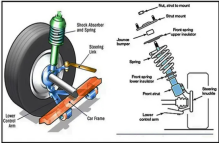

Control arms come in two variants: upper and lower control arms. As its name suggests, the upper control arm is installed on top of the wheel whereas the lower one is placed below it. Every kind has its own respective function in the suspension system. These could range from; control arms, stamped steel, cast iron and aluminum. Depending on performance requirements, selection of control arm’s material could vary in respect of weight and strength.

Of all the types of structures that can be found on a vehicle, the control arms have great influence on how that vehicle is designed or how it behaves on the road. Placement of control arms influences the car’s stability while cornering. If the control arm design is appropriate to the specs, the vehicle’s reception to steering inputs will be much faster and confidence inspiring as a result. However, bad design or worn out control arms will result in excessive rolling motion of the car body and weak overall control of the car.

Control arms do require maintenance as well, if a vehicle is expected to deliver consistent performance over a long time. When turning, a distinctive sound could be heard. There may also be signs of uneven wearing out of the tires and loss of handling ability. Frequent examination of the arms and timely appeal of the arms’ material can allow bigger problems to be avoided enabling the vehicle’s suspension system to maintain high performance standards and achieve safety.

To summarize, control arms are important aspects of vehicle control and performance. Their design, material, and proper maintenance have great effects on the performance of a car during movement on the road. With the advancement in automotive technology, the need for efficient and high-quality control arms will increase. The car owners should keep an eye on their suspension systems and think of getting good quality parts to improve their experience while driving.

The industry trends show that there is an inclination towards the adoption of lightweight materials and advanced engineering techniques in the making of control arms. The focus nowadays is geared towards more performance-oriented parts, along with decreased weight of parts which can eventually improve fuel consumption and overall vehicle handling. With electric and hybrid cars taking over the market, the need for control arms that have advanced suspension solutions will increase. It is important for all automotive people to remain up to date with this information.

EN

EN

AR

AR

PT

PT

RU

RU

ES

ES

VI

VI